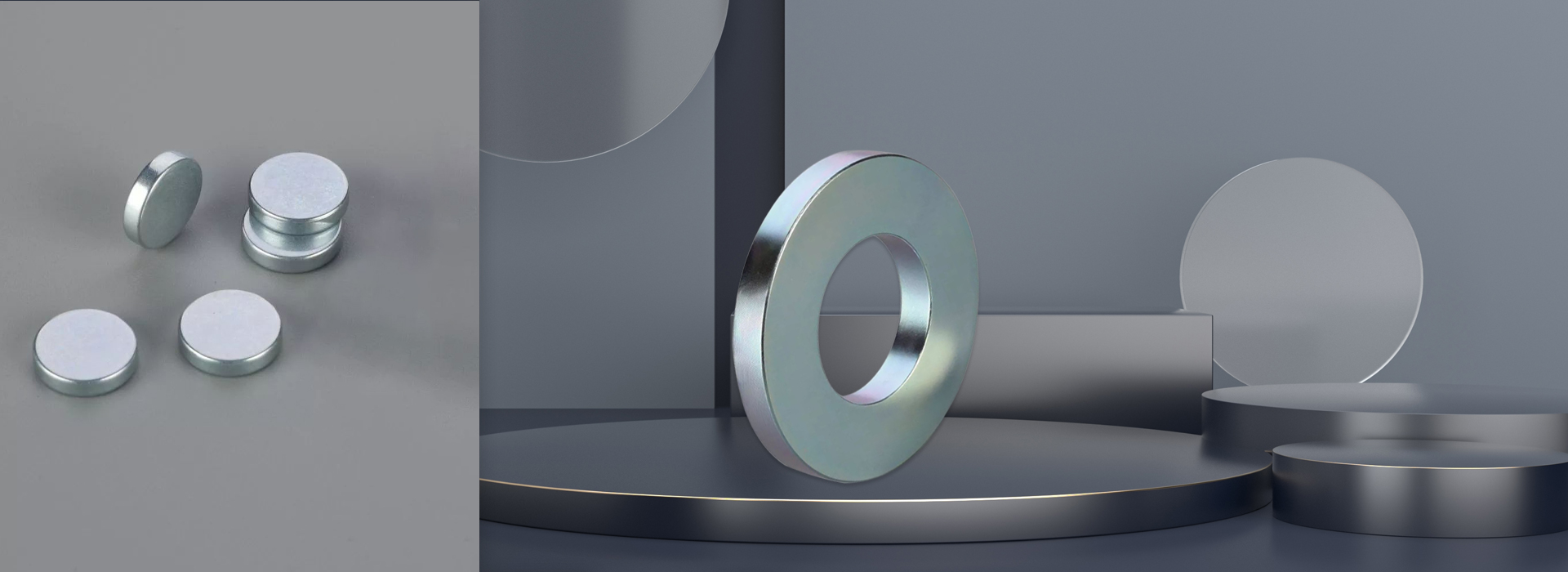

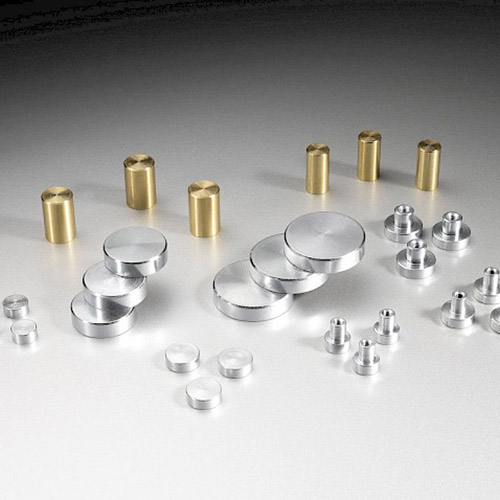

Ferrite Magnet

A Ferrite Magnet is a ceramic material made by mixing and firing large proportions of iron(III) oxide (Fe2O3, rust) blended with small proportions of one or more additional metallic elements, such as strontium, barium, manganese, nickel, and zinc.

Send Inquiry

A ferrite is a ceramic material made by mixing and firing large proportions of iron(III) oxide

(Fe2O3, rust) blended with small proportions of one or more additional metallic elements, such as

strontium, barium, manganese, nickel, and zinc. They are ferrimagnetic, meaning they can be

magnetized or attracted to a magnet. Unlike other ferromagnetic materials, most ferrites are not

electrically conductive, making them useful in applications like magnetic cores for transformers to

suppress eddy currents. Ferrites can be divided into two families based on their resistance to being

demagnetized (magnetic coercivity).

Hard ferrites have high coercivity, so are difficult to demagnetize. They are used to make permanent

magnets for applications such as refrigerator magnets, loudspeakers, and small electric motors.

Soft ferrites have low coercivity, so they easily change their magnetization and act as conductors

of magnetic fields. They are used in the electronics industry to make efficient magnetic cores

called ferrite cores for high-frequency inductors, transformers and antennas, and in various

microwave components.

Ferrite compounds are extremely low cost, being made of mostly iron oxide, and have excellent corrosion resistance. Yogoro Kato and Takeshi Takei of the Tokyo Institute of Technology synthesized the first ferrite compounds in 1930.

They are used to make permanent magnets for applications such as refrigerator magnets, loudspeakers, and

small electric motors. Soft ferrites have low coercivity, so they easily change their magnetization and act

as conductors of magnetic fields.

A ferrite magnet is able to complete within its magnetic field is up to 160 kiloampere tpm, or up to 2000

oersteds. Ferrite and ceramic magnets are considered to be permanent magnets, which are among the strongest

and most durable magnets that exist in the world.

The disadvantage is that it is easily saturated (its saturation flux density is typically < 0.5 T). By making cores with different material blends it is possible to achieve desired properties, depen-ding on whether the cores are to be used for communication purposes, power supply, filter purposes, etc.

| Material |

Remanence (Br) |

Coercive Force (Hc) |

Intrinsic Coercive Force (Hci) |

Max Energy Product (BH)max |

||||||

| mT | kG | kA/m | kOe | kA/m | kOe | kJ/m^3 | MGOe | |||

| Y8T |

200- 235 |

2.0- 2.35 |

125- 160 |

1.57- 2.01 |

210- 280 |

2.64- 3.52 |

6.5-9.5 | 0.8-1.2 | ||

| Y10T |

200- 235 |

2.0- 2.35 |

128- 160 |

1.61- 2.01 |

210- 280 |

2.64- 3.52 |

6.4-9.6 | 0.8-1.2 | ||

| Y20 |

320- 380 |

3.2-3.8 |

135- 190 |

1.70- 2.39 |

140- 195 |

1.76- 2.45 |

18.0- 22.0 |

2.3-2.8 | ||

| Y22H |

310- 360 |

3.1-3.6 |

220- 250 |

2.76- 3.14 |

280- 320 |

3.52- 4.02 |

20.0- 24.0 |

2.5-3.0 | ||

| Y23 |

320- 370 |

3.2-3.7 |

170- 190 |

2.14- 2.39 |

190- 230 |

2.39- 2.89 |

20.0- 25.5 |

2.5-3.2 | ||

| Y25 |

360- 400 |

3.6-4.0 |

135- 170 |

1.70- 2.14 |

140- 200 |

1.76- 2.51 |

22.5- 28.0 |

2.8-3.5 | ||

| Y26H |

360- 390 |

3.6-3.9 |

220- 250 |

2.76- 3.14 |

225- 255 |

2.83- 3.20 |

23.0- 28.0 |

2.9-3.5 | ||

| Y26H-1 |

360- 390 |

3.6-3.9 |

200- 250 |

2.51- 3.14 |

225- 255 |

2.83- 3.20 |

23.0- 28.0 |

2.9-3.5 | ||

| Y26H-2 |

360- 380 |

3.6-3.8 |

263- 288 |

3.30- 3.62 |

318- 350 |

4.00- 4.40 |

24.0- 28.0 |

3.0-3.5 | ||

| Y27H |

370- 400 |

3.7-4.0 |

205- 250 |

2.58- 3.14 |

210- 255 |

2.64- 3.20 |

25.0- 29.0 |

3.1-3.6 | ||

| Y28 |

370- 400 |

3.7-4.0 |

175- 210 |

2.20- 2.64 |

180- 220 |

2.26- 2.76 |

26.0- 30.0 |

3.3-3.8 | ||

| Y28H-1 |

380- 400 |

3.8-4.0 |

240- 260 |

V3.02- 3.27 |

250- 280 |

3.14- 3.52 |

27.0- 30.0 |

3.4-3.8 | ||

| Y28H-2 |

360- 380 |

3.3-3.8 |

271- 295 |

3.41- 3.71 |

382- 405 |

4.80- 5.09 |

26.0- 30.0 |

3.3-3.8 | ||

| Y30 |

370- 400 |

3.7-4.0 |

175- 210 |

2.20- 2.64 |

180- 220 |

2.26- 2.76 |

26.0- 30.0 |

3.3-3.8 | ||

| Y30BH |

380- 390 |

3.8-3.9 |

223- 235 |

2.80- 2.95 |

231- 245 |

2.90- 3.08 |

27.0- 30.0 |

3.4-3.8 | ||

| Y30H-1 |

380- 400 |

3.8-4.0 |

230- 275 |

2.89- 3.46 |

235- 290 |

2.95- 3.64 |

27.0- 32.0 |

3.4-4.0 | ||

| Y30H-2 |

395- 415 |

3.95- 4.15 |

275- 300 |

3.46- 3.77 |

310- 335 |

3.90- 4.21 |

27.0- 32.5 |

3.4-4.1 | ||

| Y32 |

400- 420 |

4.0-4.2 |

160- 190 |

2.01- 2.39 |

165- 195 |

2.07- 2.45 |

30.0- 33.5 |

3.8-4.2 | ||

| Y32H-1 |

400- 420 |

4.0-4.2 |

190- 230 |

2.39- 2.89 |

230- 250 |

2.89- 3.14 |

31.5- 35.0 |

4.0-4.4 | ||

| Y32H-2 |

400- 440 |

4.0-4.4 |

224- 240 |

2.81- 3.02 |

230- 250 |

2.89- 3.14 |

31.0- 34.0 |

3.9-4.3 | ||

| Y33 |

410- 430 |

4.1-4.3 |

220- 250 |

2.76- 3.14 |

225- 255 |

2.83- 3.20 |

31.5- 35.0 |

4.0-4.4 | ||

| Y33H |

410- 430 |

4.1-4.3 |

250- 270 |

3.14- 3.39 |

250- 275 |

3.14- 3.46 |

31.5- 35.0 |

4.0-4.4 | ||

| Y34 |

420- 440 |

4.2-4.4 |

200- 230 |

2.51- 2.89 |

205- 235 |

2.58- 2.95 |

32.5- 36.0 |

4.1-4.5 | ||

| Y35 |

430- 450 |

4.3-4.5 |

215- 239 |

v2.70- 3.00 |

217- 241 |

2.73- 3.03 |

33.1- 38.2 |

4.2-4.8 | ||

| Y30H-1 |

380- 400 |

3.8-4.0 |

230- 275 |

2.89- 3.46 |

235- 290 |

2.95- 3.64 |

27.0- 32.0 |

3.4-4.0 | ||

| Y30H-2 |

395- 415 |

3.95- 4.15 |

275- 300 |

3.46- 3.77 |

310- 335 |

3.90- 4.21 |

27.0- 32.5 |

3.4-4.1 | ||

| Y32 |

400- 420 |

4.0-4.2 |

160- 190 |

2.01- 2.39 |

165- 195 |

2.07- 2.45 |

30.0- 33.5 |

3.8-4.2 | ||

| Y32H-1 |

400- 420 |

4.0-4.2 |

190- 230 |

2.39- 2.89 |

230- 250 |

2.89- 3.14 |

31.5- 35.0 |

4.0-4.4 | ||

| Y32H-2 |

400- 440 |

4.0-4.4 |

224- 240 |

2.81- 3.02 |

230- 250 |

2.89- 3.14 |

31.0- 34.0 |

3.9-4.3 | ||

| Y33 |

410- 430 |

4.1-4.3 |

220- 250 |

2.76- 3.14 |

225- 255 |

2.83- 3.20 |

31.5- 35.0 |

4.0-4.4 | ||

| Y33H |

410- 430 |

4.1-4.3 |

250- 270 |

3.14- 3.39 |

250- 275 |

3.14- 3.46 |

31.5- 35.0 |

4.0-4.4 | ||

| Y34 |

420- 440 |

4.2-4.4 |

200- 230 |

2.51- 2.89 |

205- 235 |

2.58- 2.95 |

32.5- 36.0 |

4.1-4.5 | ||

| Y35 |

430- 450 |

4.3-4.5 |

215- 239 |

v2.70- 3.00 |

217- 241 |

2.73- 3.03 |

33.1- 38.2 |

4.2-4.8 | ||