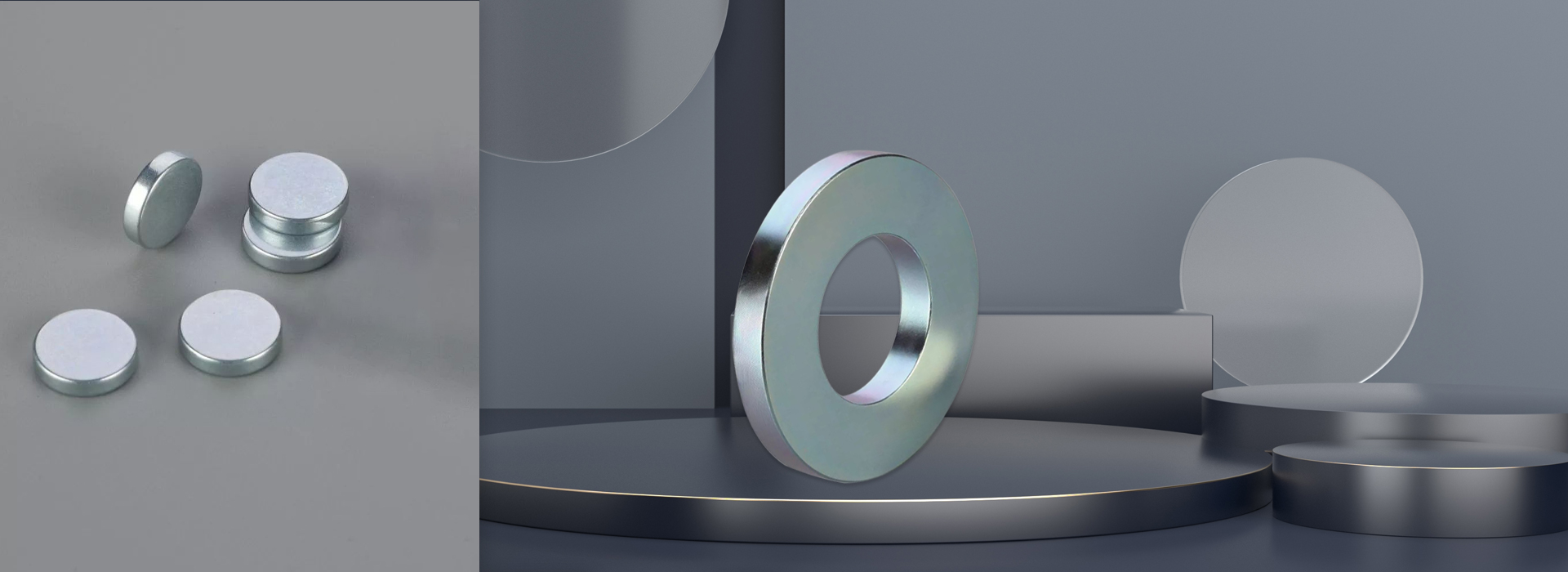

Sintered NdFeB Radiation Magnetic Ring

Sintered NdFeB radiation magnetic ring is a new product developed in recent years, and it is mainly used in high-performance permanent magnet motors and sensors.

Send Inquiry

Sintered NdFeB radiation magnetic ring is a new product developed in recent years, and it is mainly used in

high-performance permanent magnet motors and sensors.

In the application of permanent magnet motors, sintered NdFeB magnet are usually bonded into a ring, which

has a series of drawbacks:

1. The processing of tile-shaped magnets belongs to special-shaped processing. Restrictions on the

processing accuracy of angles, inner and outer surfaces, etc., make the dynamic balance of the spliced

magnetic ring poor, and the resulting transition area between the magnetic poles is larger, causing the

motor to produce noise and vibration.

2. The installed rotor has been magnetized, making manual polishing more difficult, greatly increasing the

amount of labor, and significantly increasing installation costs.

The radiation magnetic ring is an integral magnetic ring, which can maintain the consistency of the size

after processing, which can effectively reduce the noise and vibration of the motor and improve the

stability of the motor. Because the inner and outer surfaces of the entire magnetic ring can be radiated

magnetization and multi-pole magnetization at a certain angle, and the transition area between the magnetic

poles is small, the performance of the motor can be significantly improved. The surface magnetism of the

multi-stage magnetic ring is distributed in the form of the sine wave, and the ultra-high magnetic field can

greatly improve the efficiency of the motor, making the motor lightweight and miniaturized.

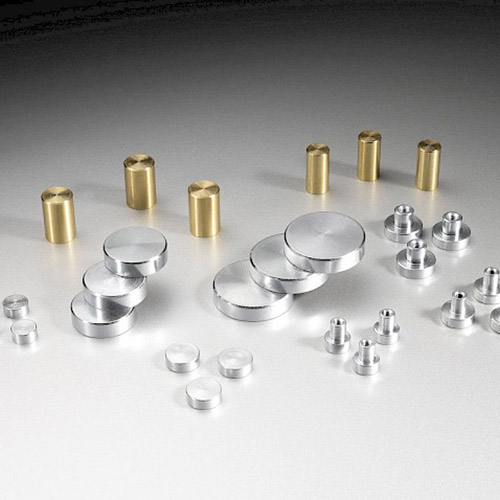

The sintered NdFeB radiation magnetic ring has a variety of magnetizing methods, and it can be unipolar

magnetized and multi-stage magnetized as required

The dimensional elements of the radiation magnetic ring include outer diameter, inner diameter, and height.

According to the outer diameter and wall thickness (inner diameter ratio), the radiation ring can be

classified as follows:

Outer Diameter

1. The outer diameter below 49mm is called a super small diameter ring.

2. The outer diameter of 50~99mm is called a small diameter ring.

3. The outer diameter of 100~149mm is called a medium diameter ring.

4. The outer diameter of 150~199mm is called a large diameter ring.

5. The outer diameter of more than 200mm is called a super large diameter ring.

Wall Thickness

1. Those with an inner diameter ratio of less than 0.7 are called thick-walled rings.

2. Those with an inner diameter ratio greater than 0.9 are called thin-walled rings.

The production process of sintered NdFeB radiation ring is complicated and difficult, so the price is

generally higher. At present, there are not many manufacturers in the world that can produce large-diameter

radiation rings with a diameter of more than 300mm. The purchaser needs to compare the technical strength

and production capacity of the manufacturers in various aspects.