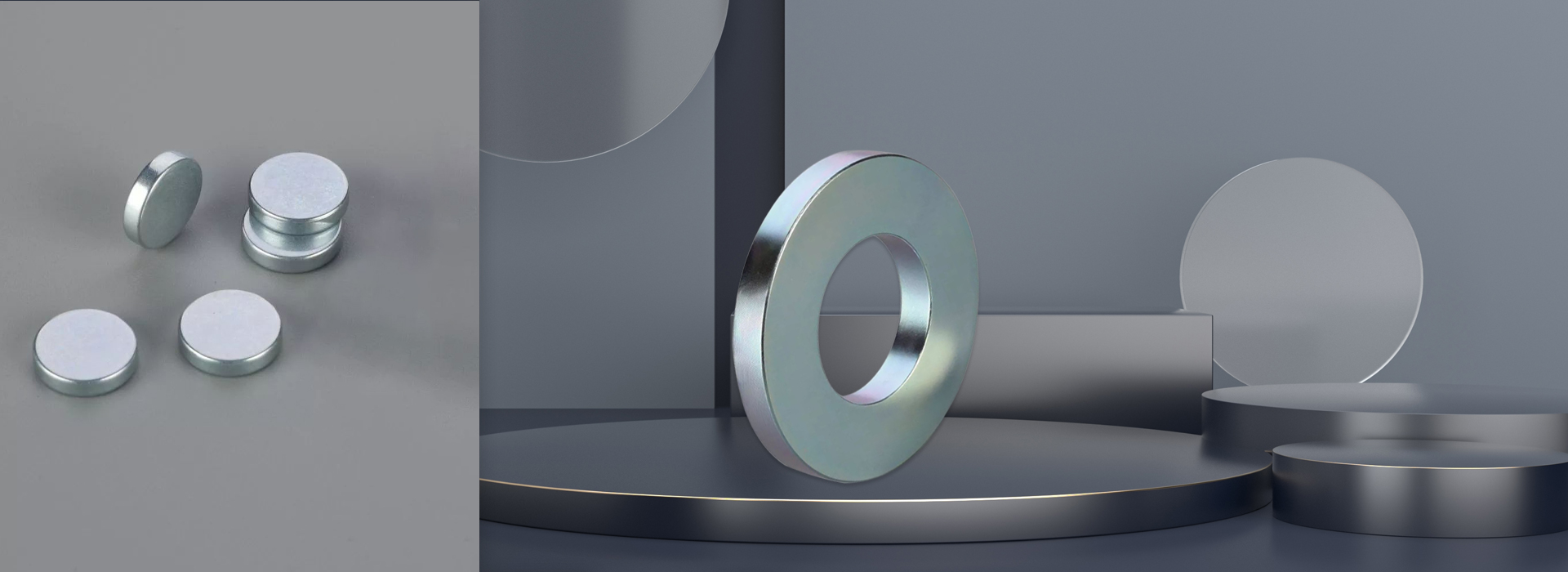

Alnico Magnet

Alnico magnets, composed of primarily aluminum (Al), nickel (Ni), and cobalt (Co), were developed in the 1940s.

Send Inquiry

Alnico magnets, composed of primarily aluminum (Al), nickel (Ni), and cobalt (Co), were developed in the

1940s.

This class of magnet remains a preferred material because of its excellent temperature stability, high

magnetic

flux density, and resistance to corrosion.

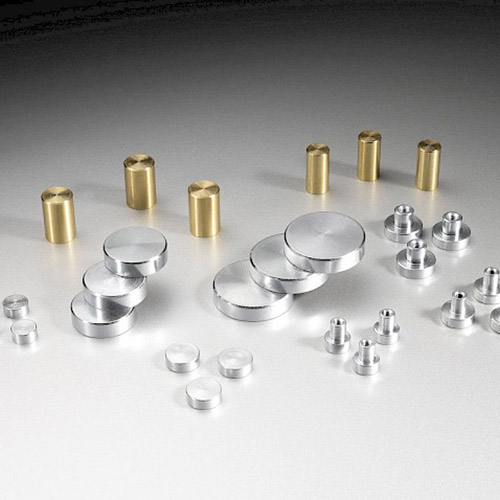

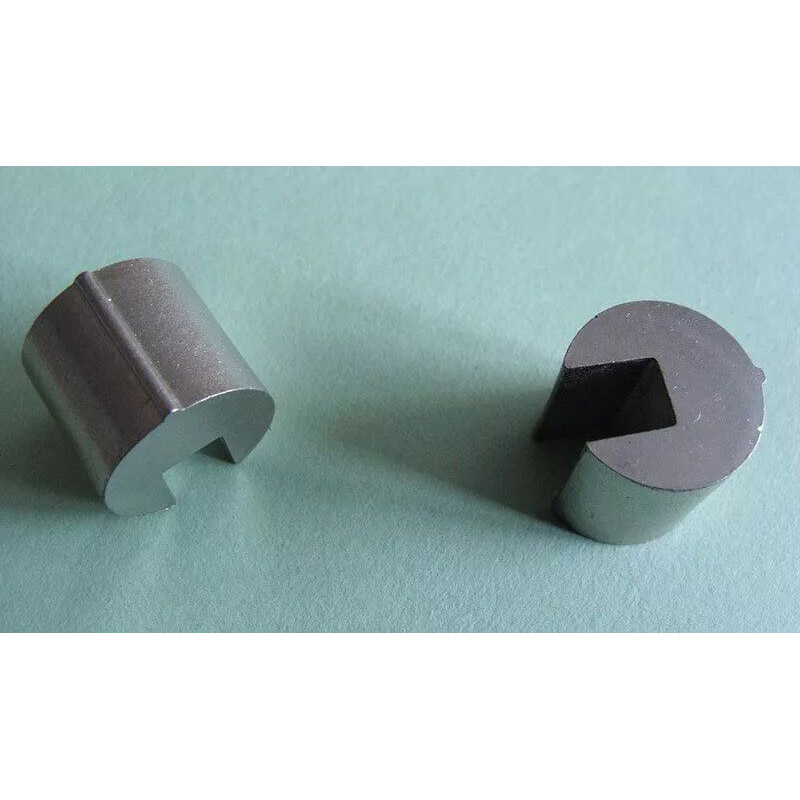

Alnico magnets are manufactured through a casting or sintering process. The casting process allows the

magnet to

be manufactured into intricate and complex shapes. Sintered Alnico is made from a powdered mixture of

ingredients that are pressed into a die under tons of pressure. The Sintering process allows for the magnets

to

be manufactured to tighter tolerances and higher mechanical strength.

| Grade |

Residual Induction Br(max) [Gs] |

Max Energy Product BH (max) MGOe |

Coercive Force Hcb Koe |

Curie Temp. [˚C] |

Temp. Coe of Br [%/˚C) |

Max. Practical Operating Temp. [˚C] |

|

|

Alnico 2 (Isotropic) |

7000 | 1.6 | 0.56 | 810 | -0.03 | 450 | QUOTE |

|

Alnico 3 (Isotropic) |

6000 | 1.2 | 0.48 | 810 | -0.03 | 450 | QUOTE |

|

Alnico 5 (Anisotropic) |

12500 | 5.5 | 0.64 | 860 | -0.02 | 525 | QUOTE |

|

Alnico 6 (Anisotropic) |

10000 | 3.5 | 0.78 | 860 | -.0.02 | 525 | QUOTE |

|

Alnico 8 (Anisotropic) |

8000 | 5.5 | 1.65 | 860 | -0.025 | 550 | QUOTE |

|

Alnico 9 (Anisotropic) |

10500 | 9.0 | 1.50 | 860 | -0.025 | 550 | QUOTE |

Br: Residual Induction

Gs: Gauss

Hc: Coercive Force

Oe: Oersted

˚C: Degree Celcius

MGOe: Mega Gauss Oersted

Standard Tolerances (inches);

Rod – Diameter (±0.002), Length (±0.005)

Rectangle – Length & Width (±0.01), Thickness (±0.005)

Ring – Outside Diameter (±0.002), Inside Diameter (±0.02), Thickness (±0.005)

They have marginally lower magnetic properties, but better mechanical properties, than cast Alnico. Their fine grain structure results in highly uniform flux distributions and mechanical strength. So they are suited for applications requiring short magnets.

See the table below for grades and properties of cast Alnico magnets.

| Grade |

Residual Induction Br(max) [Gs] |

Max Energy Product BH (max) MGOe |

Coercive Force Hcb Koe |

Curie Temp. [˚C] |

Temp. Coe of Br [%/˚C) |

Max. Practical Operating Temp. [˚C] |

|

|

SAlnico 2 (Isotropic) |

7000 | 1.55 | 0.55 | 810 | 0.008 | 450 | QUOTE |

|

SAlnico 3 (Isotropic) |

5800 | 1.20 | 0.50 | 860 | 0.011 | 550 | QUOTE |

|

SAlnico 5 (Anisotropic) |

11000 | 4.25 | 0.62 | 890 | 0.009 | 525 | QUOTE |

|

SAlnico 6 (Anisotropic) |

10000 | 3.50 | 0.79 | 850 | 0.011 | 525 | QUOTE |

|

SAlnico 8 (Anisotropic) |

8800 | 5.25 | 1.50 | 850 | 0.011 | 550 | QUOTE |

|

SAlnico 8HC (Anisotropic) |

7000 | 4.13 | 1.80 | 860 | 0.011 | 550 | QUOTE |

Br: Residual Induction

Gs: Gauss

Hc: Coercive Force

Oe: Oersted

˚C: Degree Celcius

MGOe: Mega Gauss Oersted

Standard Tolerances (inches);

Rod – Diameter (±0.002), Length (±0.005)

Rectangle – Length & Width (±0.01), Thickness (±0.005)

Ring – Outside Diameter (±0.002), Inside Diameter (±0.02), Thickness (±0.005)